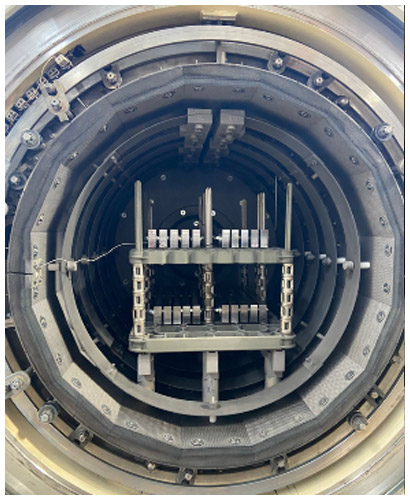

Yalman Knives applies vacuum heat treatment technology as a core manufacturing process for high-performance shear and shredder blades used in heavy-duty industrial applications. Heat treatment is a critical stage that directly determines blade hardness, toughness, wear resistance, and overall service life.

All Yalman Knives blades are vacuum heat treated under controlled and repeatable conditions to achieve an optimal balance between hardness and toughness. This process ensures:

Uniform and stable microstructure throughout the blade,

High resistance to cracking and premature failure,

Superior wear resistance on cutting edges and load-bearing areas.

Vacuum heat treatment prevents oxidation, decarburization, and surface degradation, which are common risks in conventional heat treatment methods. As a result, blade geometry and surface quality are fully preserved, providing an ideal foundation for post heat treatment CNC machining.

Our heat treatment processes are optimized specifically for industrial shear blades, single-shaft shredder blades, and dual-shaft shredder blades operating under high impact, shock loads, and continuous torque. Precise control of heating, quenching, and tempering cycles allows consistent mechanical properties in every production batch.

Combined with:

High-quality European tool steels,

Precision CNC machining after heat treatment,

Strict process monitoring and quality control,

our vacuum heat treatment technology guarantees OEM compatibility, long service life, and reliable field performance.

As a result, Yalman Knives blades deliver predictable and durable performance in demanding recycling, metal processing, and industrial cutting applications worldwide.